CAD Modeling & Engineering Support: Precision Design For Manufacturing Excellence

Your product’s success begins with precise, production-ready CAD models. At Trustbridge, our CAD Modeling & Engineering Support services bridge the gap between creative vision and manufacturable reality. Whether you're starting from a sketch, prototype, reference part, or legacy design, our engineering team transforms ideas into fully defined 3D CAD models optimized for real-world production. We combine technical modeling expertise with deep manufacturing insight — ensuring every feature, fillet, hole, and tolerance works with the processes, materials, and suppliers you plan to use. No throwaway CAD. No costly design revisions downstream. Just clean, precise files ready for quote, prototype, and scale.

Our CAD Services at a Glance

Ready to Start Your Design for Manufacturing Project?

Explore Related Services

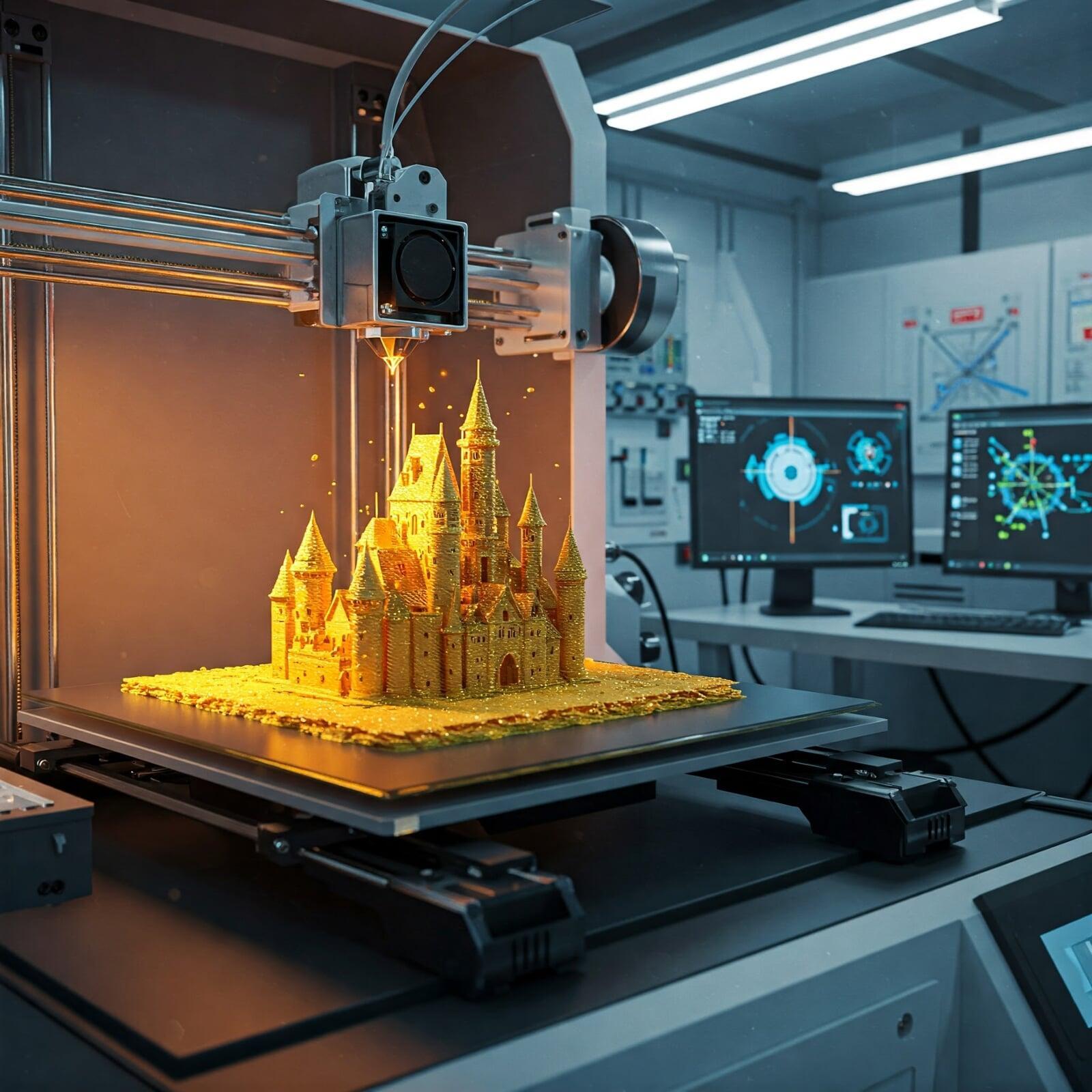

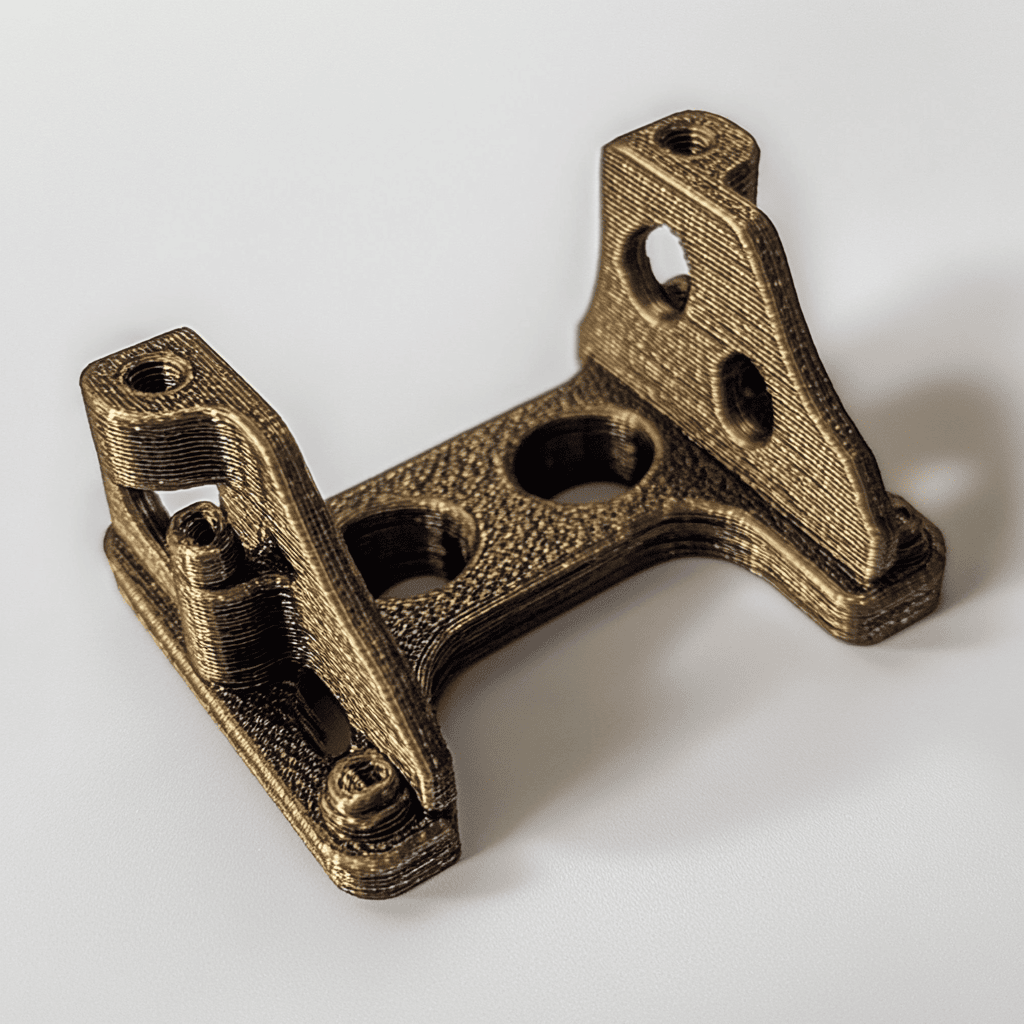

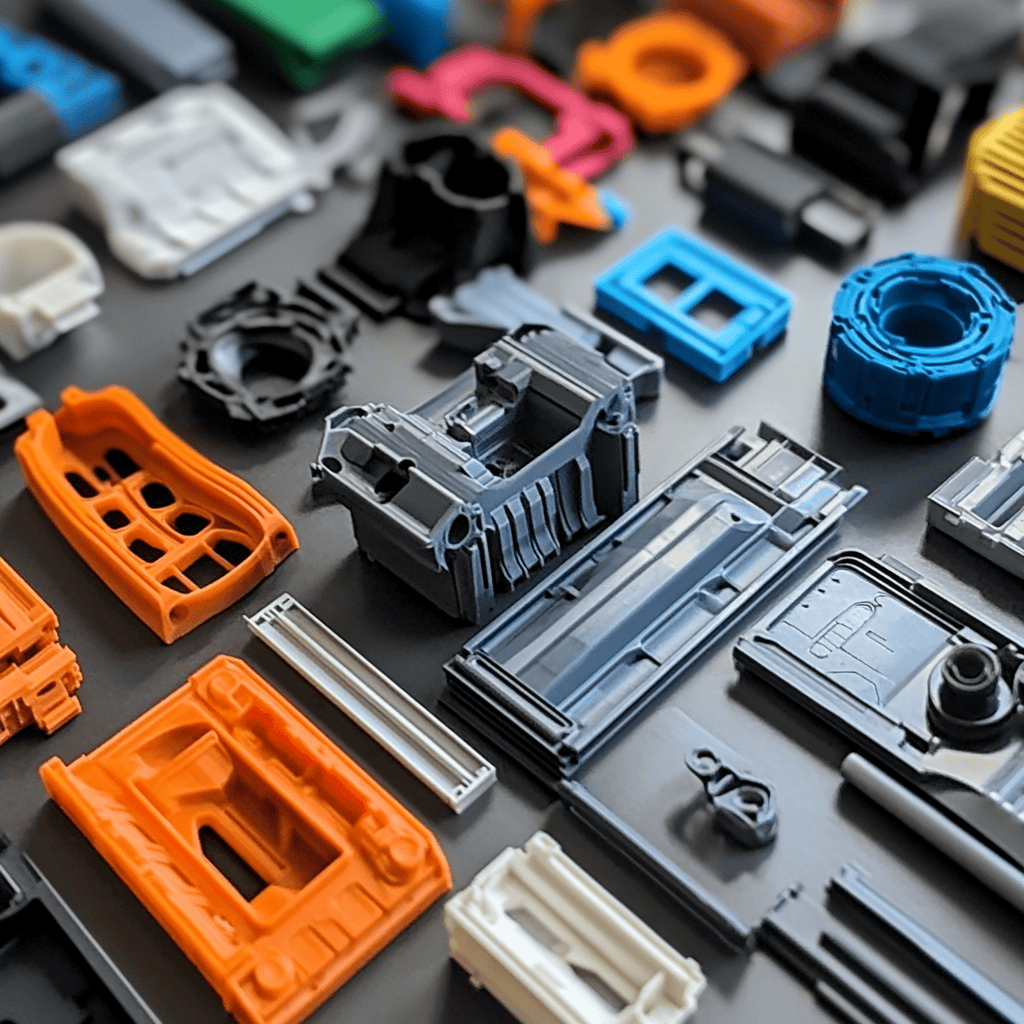

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.

Injection Molding

High-volume plastic part production with consistent quality, fast cycle times, and low per-unit cost once tooled.